The landscape of cash and e-commerce is one of competition. In fact, the brands must innovate to be set apart from competing brands. The packaging is functional and aesthetic in nature and thus can push consumers to buy and engage with a brand. Not only will it contribute greatly to profits, but also makes it especially possible for brands to keep consumers’ attention! It is understood that all types of printing need to know initially. Choosing the proper printing method forms the first step of the brand packaging process. Hence, this article will throw the spotlight on the various print mediums so that an informed decision can be made by the brand.

When it comes to custom packaging design, selecting the right print method is a vital consideration. The different print and design methods shine in their ways. And, like all technologies, so do print technologies with their applications. Below we will review the top 5 types of printing for packaging:

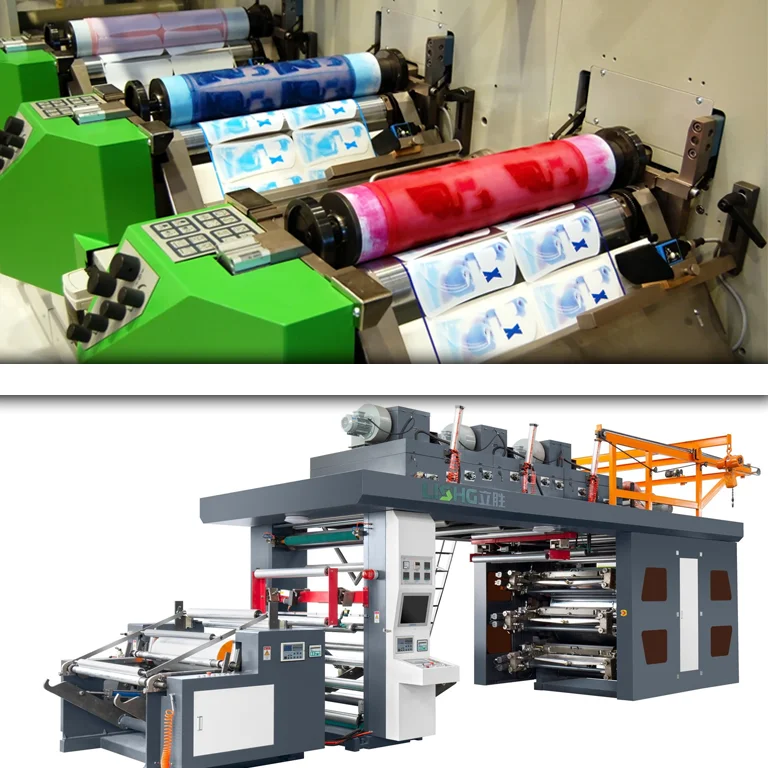

Flexographic Printing

Flexographic printing (or flexo) has been the best type printing method for many years. It provides flexible packages as well as high-volume product labels, especially in with the beverage and food industry groups.

Flexographic printing employs a flexible rubber or photopolymer relief plate which is attached as a roll around a cylinder. It is one of the main types of printing for high speed printing.

Benefits

Can print different print types or all kinds of substrates. It may be on paper, on plastic or metallic films.

Low cost per unit. Therefore, it is cheap for mass or different kinds of print types.

Designed for high speeds in the production lines, thus increasing efficiency.

Easily accomplishes most varied finishing options including die cutting and laminating.

Drawbacks

Those printed plates that are custom-made are already made fairly expensively and therefore not very economical where the quantity is lower.

This process may not be able to achieve the exact colour matching and finest detail.

The plates may break after a period of time; that means, this would affect once again the quality in future printout.

Offset Printing

Lithography sometimes known as offset printing. Commonly employed for different methods of printing. The lithography process ensures a finished image is transferred to an aluminum plate first, then transferred to a rubber blanket, which is finally printed to the substrate. Other finishes can be added for aesthetic and protective measures with coatings and varnishes.

Benefits

Provides sharp, clear images with great colour accuracy.

Works on different styles of prints including paper, cardboard, and some plastics.

After set-up costs, the per unit price is significantly lower with quantity.

Much different coating and finishing options can be used, further enhancing packaging’s visual impact.

Cons

The cost of making plates or set up can be too high to make it less economical for a short run.

It takes longer to set-up than other types of sustainable packaging.

Are less flexible for customisation in a run.

Gravure Printing

Gravure printing entails the engraving of the image onto metal cylinders. Each cylinder represented by a colour. The ink is precisely put onto the printing machine gradually building a tiner high quality image. Plus, it is used for large volumes of major types of printing for food products.

Benefits

Able to print a detailed and uniform image with very deep colours.

The engraved cylinders are quite durable allowing it for extremely high runs.

It can maintain consistency across the same large run quantities.

Challenges

The process is slow and very difficult to justify on short runs.

Gravure is not intended to design projects that require a lot of exclusive changes or customisation.

Gravure works best on very specific substrates. Between various types of printing, this option is best!

Digital Printing

Digital printing is gaining ground on the product package and it’s advancing remarkably as compared to different forms of printing such as: flexo, offset and gravure.

Digital printing is the inkjet and laser. Becomes one of the most well-known and famous sorts of all types of printing services since it is faster while its running costs and print quality are better.

Advantages

No plates. Speed in production time.

No plates mean cost savings on many smaller quantities.

Great for personalised packaging and variable data of all type printing.

Disadvantages

Not always the most cost effective medium for larger quantities.

Not all substrates are compatible with digitally printed inks.

Certain printing processes, such as lithography, are more successful in achieving precise Pantone print matches compared to other processes. For example:

Screen Printing

A design method using a woven mesh screen as a stencil through which ink is pressed through the open areas in order to reproduce said design onto a packaging substrate against a blocked area; it can also be used for printing or type of printing on rigid substrates, such as glass, wood, fabric, and plastic. Mostly, screen printing is limited in application to short or specialty runs of packages.

Advantages

A heavy ink application results in excellent, long-lasting, brilliant hues which stand up to abrasion through the life of the package.

– Screen printing is ideal for applications printing on irregular, or otherwise-curved, surfaces where other printing processes are limited.

Screen printing has the ability to provide rich, intense color, catering to most substrates, even very dark ones.

Disadvantages

The impracticality of more colors in the design is that each color requires its own screen and stencil.

More labor intensive than either digital printing or offset printing. More time-consuming when used for a high volume of orders.

Not as effective for elaborate graphics or high resolution (and thereby it’s not a great value for multi-colour designs)

Final Thought

In today’s world, packaging is not just about protecting the contents. At a higher level, in the case of new businesses, user-centered design thinking helps in brand positioning.

Understanding the difference between gloss and matte lamination, for instance, provides someone producing millions of units with the necessary details to make the best choices.

When it comes to improving a company’s image, choosing the right design also means creating an adventure with the packaging for the product while preserving and guarding it, and most importantly, catching the user’s attention.